If you have been following our production department updates you will know that our production team has been working on making improvements to our fleet of guest boats. With most of the major carpentry completed painting is underway.

Painting is a four-step process using marine grade paints that not only make the boats look beautiful but are important for waterproofing and sealing the wood and fiberglass. The first step is sanding to remove a year’s worth of built-up dirt, algae, barnacles, and chipping paint. Next, minor dents and dings are patched and filled with polyester resin-based wood Bondo.

After the surface is prepped and smoothed it is cleaned. Then an epoxy-based primer coat is applied. The last step in the process is to finish painting.

There are four different paints in this step; most of the exterior of each boat gets painted with black yacht enamel and the gunwales are accented in red. The interior of the boats gets several coats of exterior grade acrylic paint while the underside up to just above the water-line gets painted with marine anti-fouling paint. The anti-fouling paint contains copper which is naturally anti-microbial and will lessen the build-up of barnacle growth on the boat.

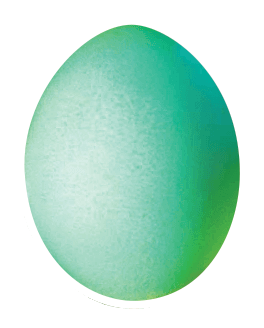

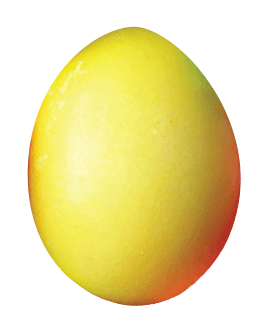

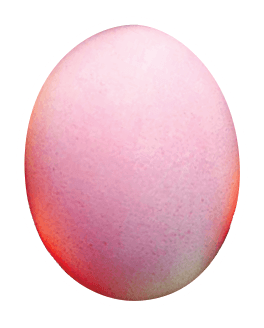

Here are some more photos from the production shop.

About the author

I've worked at WaterFire Providence since 2003. For the first 9 years of my career, I worked in the Production Shop learning all of the details that go into the physical production of the event. In 2012 transitioned to the role of managing WaterFire's social media and web presence. I now head up WaterFire Providence's digital projects including, web, social, databases, and our physical IT infrastructure.

Citing the steps of the process in painting the boat, I can see that the paint would last longer. I can say that it turned out to be beautiful and I’m sure that the wood and fiberglass is already waterproof and sealed after the process.